Friday

3D Printer Innovation

__

The goal of this project is to innovate a current 3D printer into a new one that is easily modifiable, multifunctional, user-friendly, and allow for unlimited color combinations. Through Systematic Innovative Thinking (SIT) method, Friday was created as a futuristic 3D printer, designed for start-ups, hobbyists, and students.

Tools: Team Project (with Stephen Kane & Sam Mei)

Duration: 6 weeks

Category: Appliances Design

Duration: 6 weeks

Category: Appliances Design

Innovation research

SIT method was applied to each individual component of a standard 3D printer to ideate new and creative functions it could hold. We also looked into many emerging technologies that we could incorporate into our printer.

3D printing in color

By using a system of pellet filaments of five different key colors, Friday allows users to 3D print their CAD in color

Pellet Print Head

The print head allows for a pellet 3D printing system thanks to integrated melting system.

Modular Built

Friday provides users the ability to swap components easily, allowing them to adjust print bed size, or switch the print head for a different module like a laser engraver or a lidar. This makes Friday not just a 3D printer, but also an engraver, and a 3D scanner.

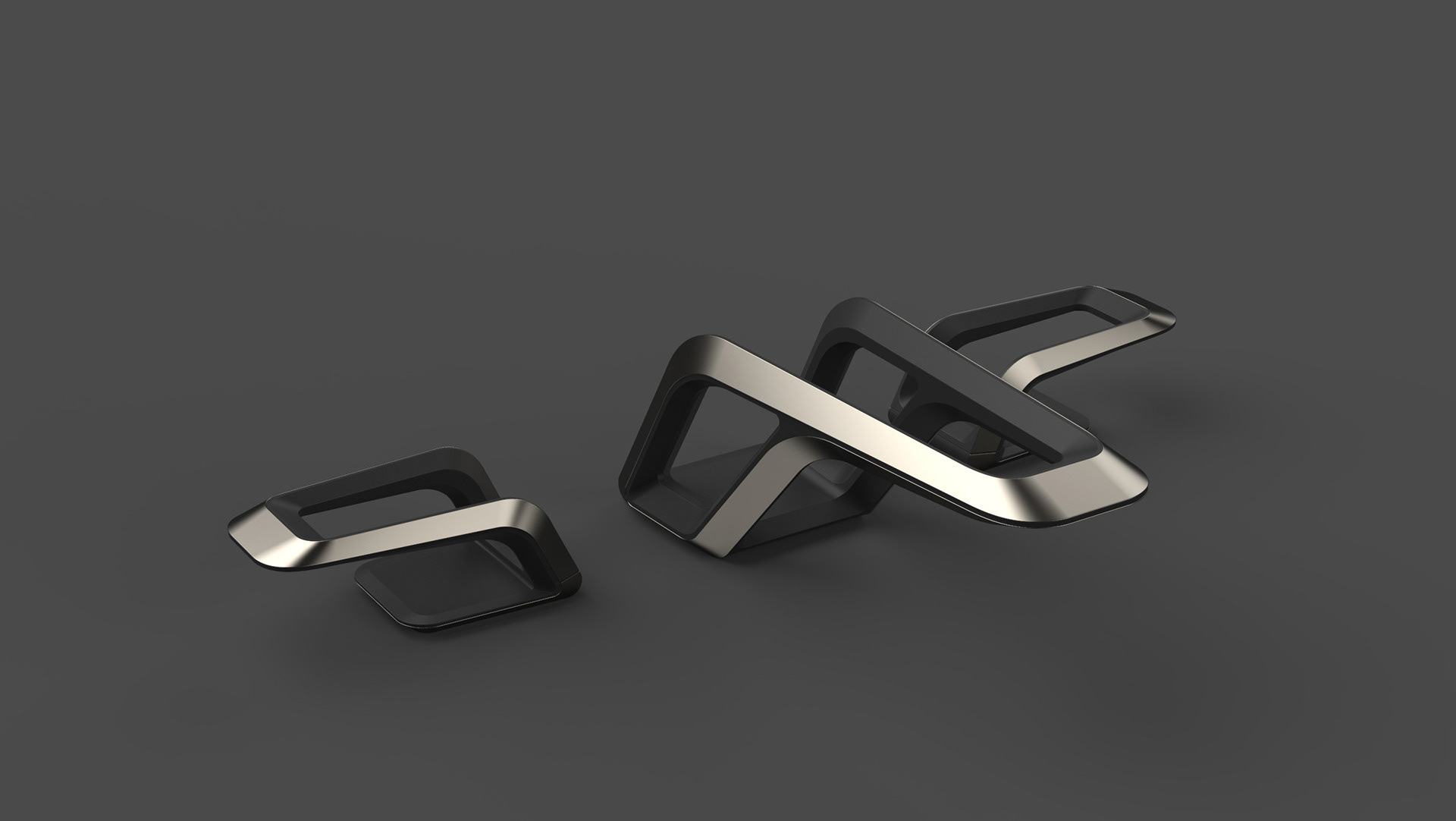

Swapping Heads

Modules can be swapped by disengaging the pins within the Y-axis arm and inserting a new one. These pins also function as the power source.

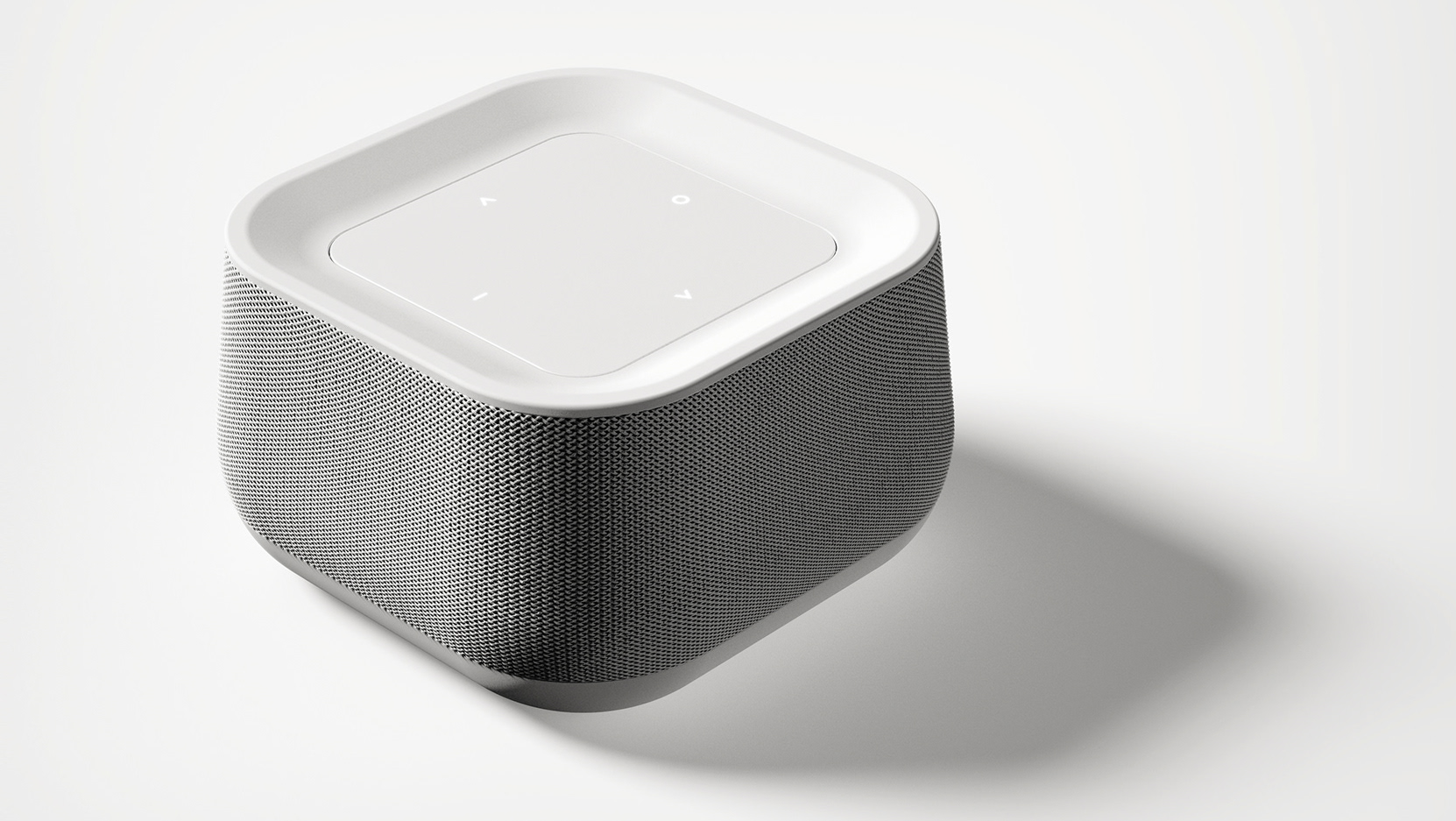

Easy Control

A simple and intuitive interface screen to help users control the machine, navigate through modes and get information about their printing progress.